Trimming, packaging, freezing

At Brakel, we handle the manual trimming of chicken quarters, the resulting meat is packaged and frozen according to our Customers' orders.

About the company

Meat trimming plant for chicken quarters

The plant we operate is located in Koszyce (Małopolskie Voivodeship). We handle the trimming, packaging and freezing of poultry meat according to our customers' requirements. We produce skinless whole leg meat, whole leg meat with skin, trimmed thigh meat, trimmed drumstick meat, poultry skins, poultry bones and quartered backs. We package the meat in:

- 10kg, 15kg, and 20kg polyblocks,

- VAC from 0.5kg to 5kg

- MAP,

- 10kg, 12kg, 15kg, and 20kg cartons.

Our offer

Check out our offer.

Backs

We offer high quality chicken backs. Although our customers are mainly PetFood production plants, we also offer them to individual customers.

Bones

We sell poultry bones. They are usually packed fresh and in bulk. We encourage the purchase of larger quantities.

Skins

We carefully separate the poultry skins from the meat and clean them. They are suitable for further processing in production facilities.

Meat

Our trimmed poultry meat is characterised by its quality and freshness, as it only comes from reliable suppliers. Because it is obtained by manual trimming, it is not frayed/torn like machine-separated meat. Apart from the mandatory salmonella testing, we also test the meat for e coli and listeria.

Quality control

Thanks to the HACCP System and GHP/GMP principles, Brakel offers products characterised by guaranteed quality and safety.

Each of our products is verified organoleptically and using a metal detector by the quality department.

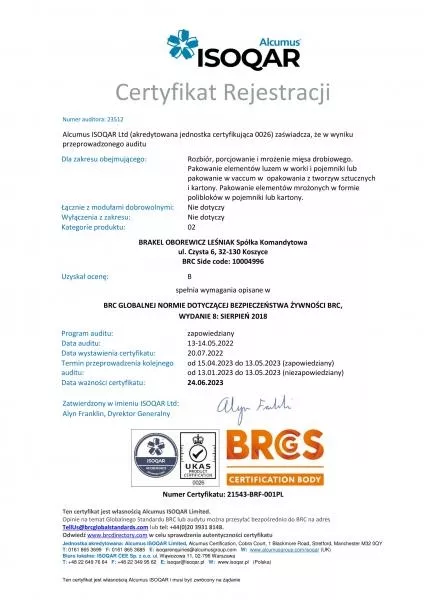

Our efforts are confirmed by the implementation of the IFS and BRC quality management systems in July 2022.

Certificate number: 21543-BRF-001PL

Location

| Brakel Oborewicz Leśniak Spółka Komandytowa ul. Czysta 6 32-130 Koszyce NIP: PL6821770624 Regon: 361071687 Sąd Rejonowy dla Krakowa Śródmieścia w Krakowie XII Wydział Gospodarczy Krajowego Rejestru Sądowego KRS 0000876227 |

Telephone:

Sales department:

![]() Dagmara Leśniak +48 509 011 965

Dagmara Leśniak +48 509 011 965

|

This email address is being protected from spambots. You need JavaScript enabled to view it. |

Quality department:

![]() Paulina Oborewicz +48 663 145 344

Paulina Oborewicz +48 663 145 344

|

This email address is being protected from spambots. You need JavaScript enabled to view it. |

Chief executive officer:![]() Sebastian Oborewicz +48 512 212 120

Sebastian Oborewicz +48 512 212 120

|

This email address is being protected from spambots. You need JavaScript enabled to view it. |

Accounting department:

![]() Karolina Pisz-Pelekh +48 503 755 494

Karolina Pisz-Pelekh +48 503 755 494

|

This email address is being protected from spambots. You need JavaScript enabled to view it. |

|

This email address is being protected from spambots. You need JavaScript enabled to view it. |

Contact